Two-post hydraulic stamping press – PST

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

High-Performance Two-Post Hydraulic Stamping Press for Sheet Metal Forming & Assembly

(Boost Your Workshop Efficiency with a Robust and Versatile Hydraulic Press)

Looking for a reliable and powerful two-post hydraulic press designed for a range of metalworking applications? Our PST series press is engineered for precision in stamping, efficient sheet metal deformation, and secure assembly tasks, making it an indispensable asset for any modern workshop.

Robust Construction for Lasting Performance: H-Frame Hydraulic Press

The PST press boasts a monolithic frame, expertly assembled and TIG welded with internal reinforcements. This robust construction ensures exceptional rigidity and durability, providing consistent performance and a long service life for your demanding industrial needs.

Precision and Versatility: Upper and Lower Tables with T-Slots

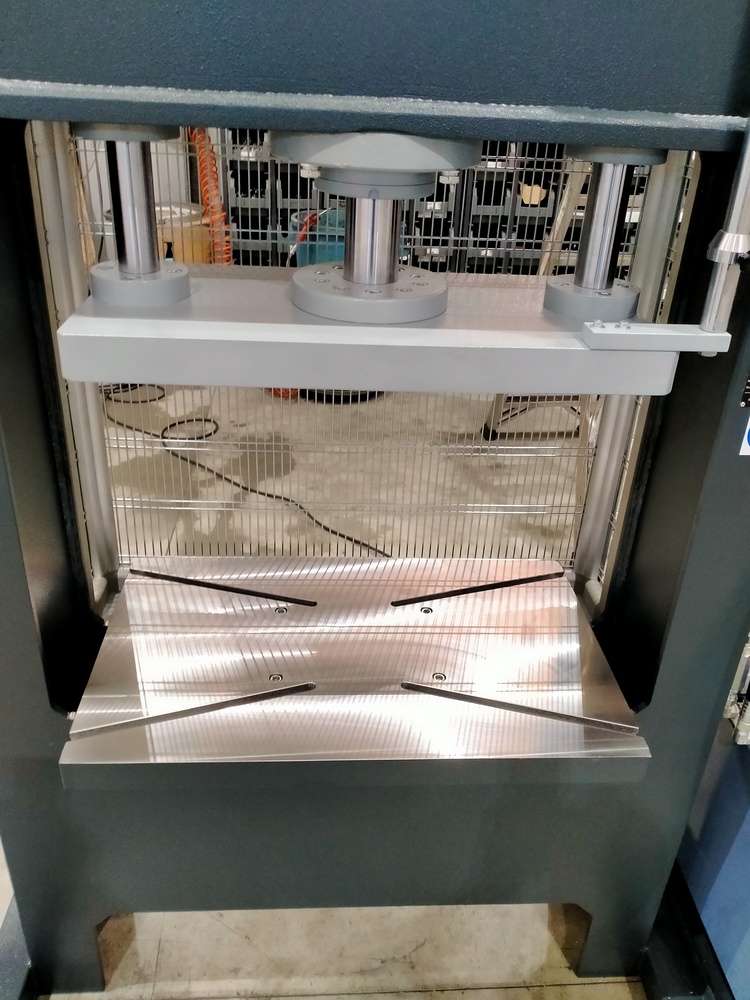

The mobile upper plane of our two-post hydraulic press features two self-lubricating guides as standard for models up to 200 tons, and four guides for the more powerful 300 and 400-ton models. This ensures smooth and precise movement during operation. It is also equipped with T-slots for secure and flexible mold fixing.

The lower table is securely bolted to the frame and also features T-slots, providing a stable and adaptable platform for various tooling and workpiece configurations.

(Primary keywords: two-post hydraulic press, hydraulic stamping press, sheet metal deformation press, hydraulic assembly press)

What are the key applications of a two-post hydraulic press?

A versatile two-post hydraulic press like our PST series is ideal for a wide range of workshop applications, including:

- Stamping: Creating precise shapes and forms in metal sheets.

- Sheet Metal Deformation: Bending, forming, and shaping metal components.

- Assembly: Press-fitting parts and components together securely.

Optimized Hydraulic Control for Efficient Operation

The hydraulic control unit of the PST press features two operating speeds: a rapid approach speed under 30 mm/sec to quickly reach the workpiece, and a slower, more powerful working speed that automatically activates upon contact with the material. This two-speed system optimizes cycle times and ensures precise forming.

Choose Your Power and Control: 40 to 400 Ton Models with Semi-Automatic and Automatic Options

The PST electro-hydraulic press is available in a comprehensive range of capacities, starting from 40 tons up to a powerful 400 tons, allowing you to select the perfect model for your specific application requirements. We also offer both semi-automatic and automatic operation to match your workflow needs.

Understanding Semi-Automatic Operation

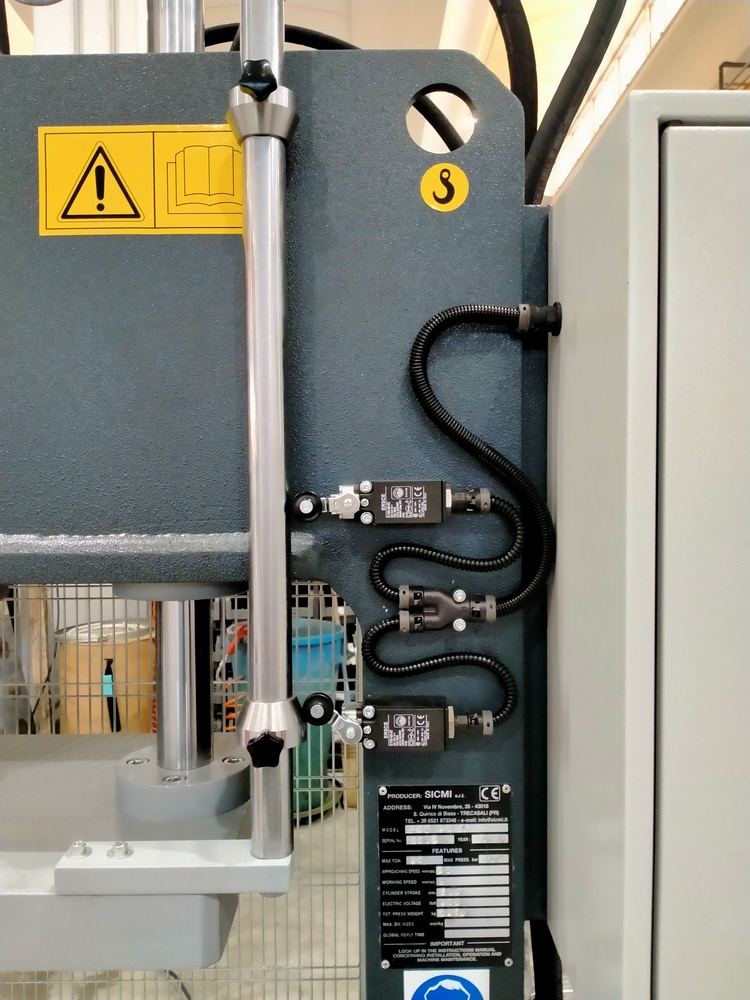

The semi-automatic version requires the simultaneous use of the lever and the ignition button for enhanced operator safety. It is equipped with rod end stroke sensors that precisely control the ascent and descent of the hydraulic cylinder. Additionally, this H-frame hydraulic stamping press comes standard with a rod anti-rotation device for increased accuracy and safety.

Benefits of Automatic Operation

The automatic version of the PST electro-hydraulic press can be operated using simultaneous double button control and also features cylinder limit switches for precise stroke control. The rising of the work surface is automatic, further streamlining the production process. This advanced version includes the integration of a reliable Siemens PLC and high-performance Rexroth solenoid valves, ensuring consistent and dependable operation.

User-Friendly Controls for Enhanced Productivity

The PST workshop press machine is equipped with a pedestal-mounted console that houses all major controls, providing easy access and a comfortable operating experience for your technicians.