Ultra-High-Speed C-Frame Hydraulic Stamping Press – GNP

Do you want different features ?

CONTACT THE SICMI EXPERTS

Our design experts are able to provide you with specific and personalized advice based on your needs and guarantee the best performance.

Ultra-High-Speed C-Frame Hydraulic Stamping Press for High-Volume Deep Drawing

(Maximize Your Production with Blazing Fast Cycles Up to 350 mm/sec)

Looking for an ultra-high-speed C-frame hydraulic stamping press designed for demanding sheet metal pressing and deep cold deformation (drawing) operations with exceptional production cycles? Our GNP electro-hydraulic press is engineered to deliver unparalleled speed and precision, achieving a cylinder approach speed of up to 350 mm/sec to meet the needs of high-volume manufacturing.

Dual Hydraulic Drives for Precision and Control in High-Speed Forming

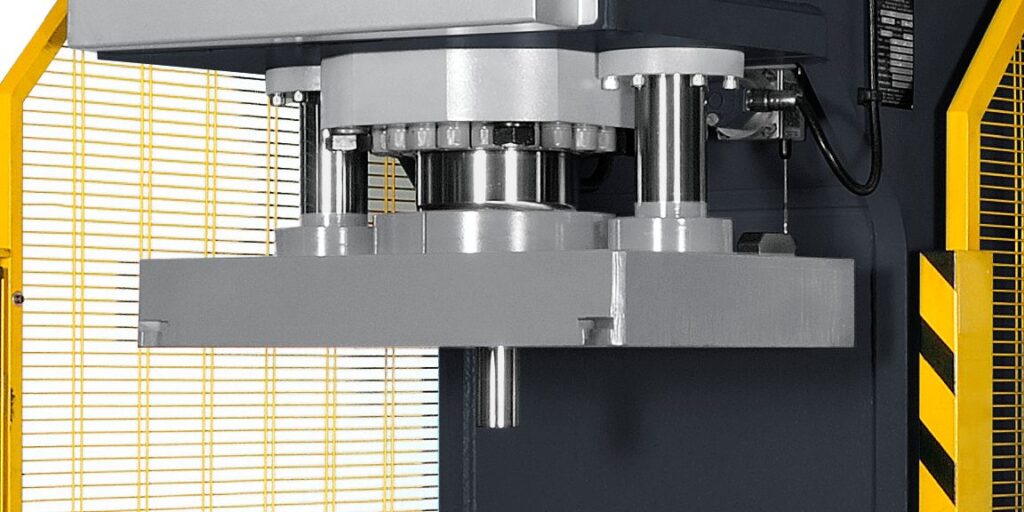

The GNP electro-hydraulic press features two independent main hydraulic drives:

- Main Slide: Generates the precise stroke and deformation load required for high-quality sheet metal forming.

- Blank Holder Cushion: Ensures controlled material flow during deep drawing, preventing wrinkling and ensuring consistent part geometry at high speeds.

This advanced dual-drive system makes the GNP workshop press ideal for fast, precise, and completely safe machining, thanks to integrated two-hand control and light barriers. The intuitive CNC system further allows for the customization and management of complex processing cycles, optimizing efficiency for high-volume production.

High-Capacity Performance: Models from 40 to 160 Tons

The GNP C-Frame hydraulic stamping press is available in a range of tonnages from 40 to 160 tons, allowing you to select the perfect machine to match your specific high-volume production requirements.

Key Features Defining the Quality of Our High-Speed Hydraulic Press:

- Rigid Electro-Welded Steel Structure: Engineered for maximum stiffness and minimal deflection under maximum load, ensuring perfect functionality and consistent part quality during continuous high-speed operation.

- Dedicated Deep Drawing Cylinders: Precision-engineered press cylinder and blank holder cylinder specifically designed for efficient and accurate deep drawing processes at high speeds.

- Intuitive Siemens Digital Control with Touch-Screen Display: Simplifies the setting of quotas and precise management of processing times for optimized high-volume production.

- High-Efficiency Hydraulic Unit: Equipped with a variable flow pump and monitored solenoid valves for precise control and energy-efficient high-speed operation.

- CE Certification – Annex IV: Demonstrates compliance with stringent European safety standards for industrial machinery.

Further Standard Equipment for Reliable High-Volume Production:

- Air / Oil Heat Exchanger: Maintains optimal hydraulic fluid temperature for consistent performance during continuous high-speed cycles.

- Decompression Valve: Ensures controlled pressure release for smooth and efficient operation.

- Working Pressure Switch: Provides accurate monitoring of the working pressure for consistent forming results.

- High-Quality Rexroth Hydraulic Components: Ensures reliability and longevity in demanding high-speed production environments.

- Dependable Siemens PLCs: Provides robust and reliable control for automated high-volume processing.

- Sliding Metal Side Protection Grills with Safety Sensors: Offers enhanced operator safety during high-speed operation, automatically stopping the press if opened.