Transforming how America sees hydraulic press manufacturing isn’t just our mission: it’s our daily reality. For the past year, our team at Lakeshore Machine & Tool has been working tirelessly behind the scenes to reshape the US market’s understanding of SICMI’s exceptional hydraulic press technology and what it means to buy direct from the source.

While most companies talk about innovation, we’ve been quietly revolutionizing how professional workshops, recycling centers, and manufacturing facilities access world-class Italian engineering. Today, we’re pulling back the curtain on exactly how we’re making this transformation happen.

The Challenge We Set Out to Solve

When we began this comprehensive rebranding initiative, we discovered something striking: the US market had become accustomed to fragmented distribution channels and inflated pricing structures that separated end-users from the manufacturers who actually build their equipment.

Professional mechanics, shop owners, and facility managers were paying premium prices for equipment while having limited access to direct technical support, customization options, and authentic replacement parts. This disconnect wasn’t just inefficient: it was fundamentally changing how American businesses viewed hydraulic press technology.

Our team recognized that SICMI’s four decades of Italian engineering excellence deserved better representation in the American market. We weren’t just looking to sell equipment; we were committed to educating an entire industry about the advantages of direct manufacturer relationships.

In the U.S., Lakeshore Machine & Tool is SICMI’s exclusive partner and local expert—please route all inquiries, quotes, and custom requests through our Michigan office.

Our Multi-Pronged Education Strategy

Rebuilding market perception requires more than new logos and updated websites. Our team developed a comprehensive education strategy that touches every aspect of how customers discover, evaluate, and purchase hydraulic press equipment.

Technical Content Development

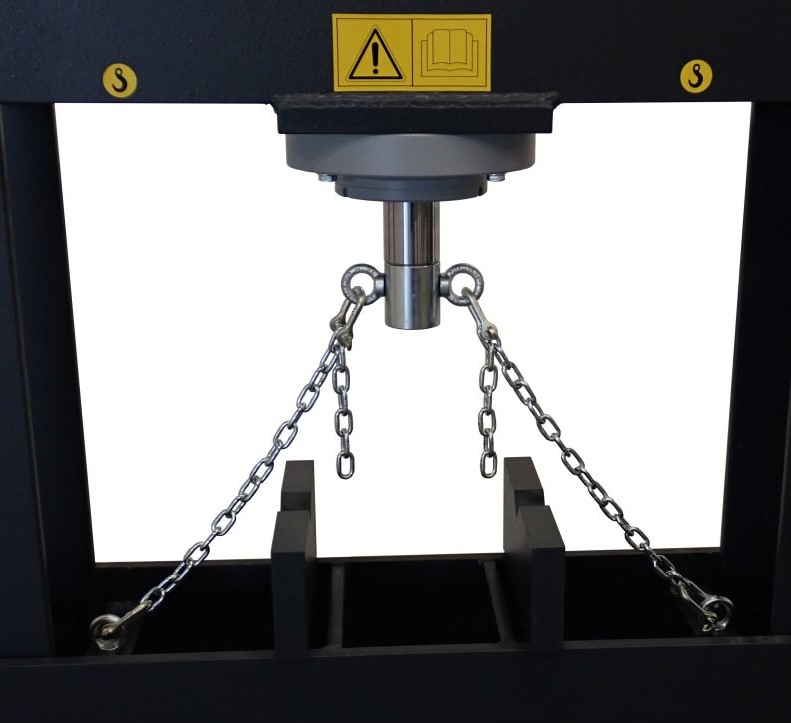

Our engineering team has been working closely with SICMI’s Italian specialists to create the most comprehensive technical documentation available in the US market. Every hydraulic straightening press, tire press, and custom molding solution now comes with detailed specifications that help customers understand exactly what they’re purchasing.

Instead of generic product descriptions, we’re providing application-specific guidance that helps shops determine the precise tonnage, bed dimensions, and control systems they need for their unique requirements. This level of detail reflects our commitment to informed purchasing decisions rather than simple transactions.

Direct Communication Channels

Perhaps most importantly, we’ve established direct communication pathways between US customers and SICMI’s engineering team. When a recycling center needs a custom tire press configuration or a machine shop requires specific hydraulic workshop press specifications, they can now speak directly with the engineers who design these systems.

This isn’t just customer service: it’s collaborative engineering. Our customers are gaining access to the same technical expertise that European manufacturers have relied on for decades.

In the United States, Lakeshore Machine & Tool is SICMI’s exclusive partner and local experts. The Lakeshore Machine team are available to review, coordinate, and facilitate all facets of your purchase from build to ship. Direct all quotes, orders, and service requests through our Michigan office.

Behind-the-Scenes Team Efforts

Market Research and Customer Feedback

Our sales and engineering teams have conducted extensive market research across the US, visiting manufacturing facilities, auto shops, and recycling centers to understand exactly how hydraulic press equipment is being used in real-world applications.

This grassroots approach has revealed significant gaps between what distributors were offering and what end-users actually needed. Many shops were over-purchasing capacity they didn’t need or under-specifying critical features that would improve their productivity.

Partnership Development

While we’re focused on direct relationships, we also recognize that established distributors and equipment dealers play valuable roles in their local markets. Our team has been working to develop partnership models that preserve these relationships while ensuring customers receive authentic SICMI equipment with proper technical support.

These partnerships aren’t about cutting costs: they’re about ensuring every customer receives genuine value regardless of how they prefer to purchase equipment.

Training and Certification Programs

Our most ambitious behind-the-scenes effort has been developing comprehensive training programs for both our internal team and external partners. Every Lakeshore team member understands the specific applications and advantages of SICMI’s various hydraulic press configurations.

This expertise translates directly into better customer outcomes. When a facility manager calls with questions about hydraulic straightening press capabilities, they’re speaking with someone who understands both the technical specifications and practical applications.

Tangible Benefits for Distributors

Streamlined Procurement

Equipment distributors working with Lakeshore now have access to simplified ordering processes, standardized pricing structures, and guaranteed delivery timelines. Instead of navigating complex international relationships, distributors can focus on what they do best: serving their local customer base.

Technical Support Partnership

We’ve established comprehensive technical support partnerships that ensure distributors can provide authoritative answers to customer questions. This isn’t just product information: it’s engineering expertise that helps distributors compete more effectively in their markets.

Inventory Optimization

Our demand forecasting and inventory management systems help distributors optimize their equipment inventory without carrying excessive working capital. Predictable delivery schedules and standardized configurations reduce the financial risks associated with hydraulic press inventory.

Direct Benefits for End-Users

Authentic Equipment Guarantee

Every hydraulic press purchased through our rebranded network comes with guaranteed authenticity and full 1 yr manufacturer warranty coverage. End-users no longer need to worry about counterfeit components, unauthorized modifications, or voided warranties.

Customization Access

Perhaps most significantly, end-users now have direct access to SICMI’s customization capabilities. Whether they need specific bed dimensions, custom control systems, or specialized tooling configurations, customers can work directly with the engineering team that designs these systems.

Lifecycle Support

Our comprehensive lifecycle support program ensures that customers receive ongoing technical assistance, genuine replacement parts, and upgrade opportunities throughout their equipment’s operational life.

Looking Forward: The Vision We’re Building

Our rebranding efforts extend far beyond marketing and sales. We’re building the foundation for long-term partnerships that will transform how American businesses approach hydraulic press technology.

Industry Education

We’re committed to ongoing industry education that helps customers make informed decisions about hydraulic press applications. This includes technical seminars, application workshops, and direct access to SICMI’s engineering expertise.

Technology Integration

As manufacturing technology continues evolving, our direct manufacturer relationship ensures US customers have immediate access to SICMI’s latest innovations, from advanced control systems to automated handling solutions.

The Transformation Continues

This rebranding initiative represents more than business strategy: it’s our commitment to American manufacturing excellence. By connecting US businesses directly with SICMI’s proven engineering capabilities, we’re ensuring that professional workshops, recycling facilities, and manufacturing operations have access to the same quality and innovation that European businesses have relied on for decades.

Every hydraulic press we deliver, every customer relationship we build, and every technical solution we provide contributes to this larger transformation. We’re not just selling equipment; we’re building the foundation for more efficient, more capable, and more competitive American manufacturing.

The behind-the-scenes work continues every day, driven by our unwavering commitment to customer success and our belief that direct manufacturer relationships represent the future of industrial equipment procurement.

Ready to experience the difference that direct SICMI partnership can make for your operation? Contact Lakeshore Machine & Tool—SICMI’s exclusive U.S. expert at our Michigan office to discuss your specific hydraulic press requirements and discover how our comprehensive rebranding initiative translates into tangible benefits for your business.